The RF Ablation Connector Market Is Segmented

Into Two Main Categories

PUSH PULL STYLE CONNECTORS

OVER MOLDED BANANA PLUGS

PUSH PULL STYLE CONNECTORS

RF ablation push pull style connectors offer additional function and space saving benefits.

DESIGN CONSIDERATIONS

1-30+ CONTACTS

Push pull connector housings protect pins from damage allowing for

miniaturization of the contacts. Smaller contacts have lower retention

forces therefore allowing for high contact counts with acceptable

insertion withdrawal forces.

LOCKING, BREAKAWAY, OR NON-LOCKING

Nonlocking and breakaway connectors rely on acceptable contact

forces and housing interference to achieve desired insertion

extraction forces. Additional components are required to achieve

locking functionality.

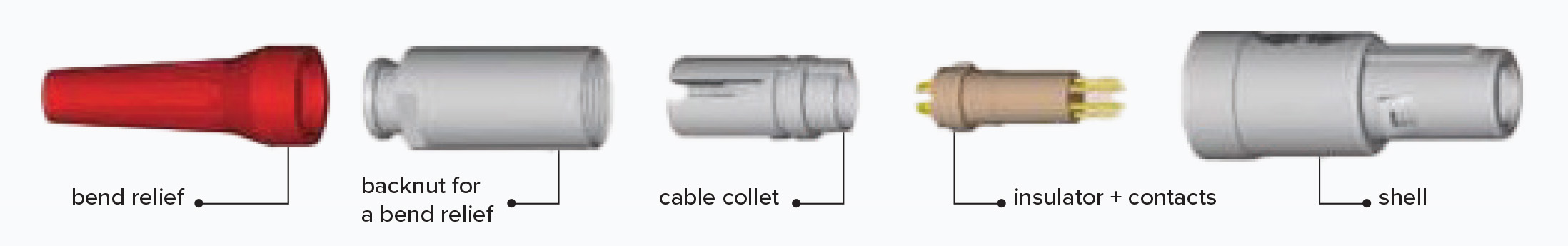

PLASTIC, METAL, OR HYBRID HOUSINGS

The connector housing can be made out of plastic, metal, or a hybrid

of both metal and plastic allowing for a range of durability.

HIGH CONTACT DENSITY

After the contact insulator is molded the contacts are either press fit

or snapped (crimp and poke) into place. This assembly process and

the ability to miniaturize the contacts allows for high contact density.

PUSH PULL COST DRIVERS

IN ORDER OF MAGNITUDE

1. CONTACTS

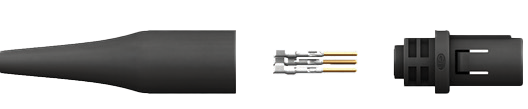

STAMPED CONTACTS

• Less than $0.02 each at volume

• Recommended for high volumes

• Crimp and poke assembly requires the least amount of labor

• Cannot be potted in epoxy or over molded easily

MACHINED CONTACTS

• Less than $0.10 each at volume

• Utilized for small to medium volume

• Press fit then soldered which can be more labor intensive

• Used when ingression protection is a concern.

2. CONTACT PLATING

DISPOSABLE APPLICATIONS

• Less than $0.01 each at volume

• <10 insertion extraction cycles

• Less than 10μ” gold plating

• Stamped contacts can utilize selective gold plating

further optimizing costs.

REUSABLE APPLICATIONS

• Less than $0.25 each at volume

• 2,500+ insertion extraction cycles

• Minimum thickness of 30μ” gold plating

• Contacts with 30μ” gold plating will cost 4x more

than gold flash contacts.

4. PLASTIC MATERIAL

Without being exposed to high temperatures during soldering, crimp and poke stamped contacts can be paired with ABS contact insulators. ABS is the lowest cost contact insulator material and recommended for disposable applications. For multiple use applications requiring sterilization, plastics and metals can be carefully selected to optimize cost and performance.

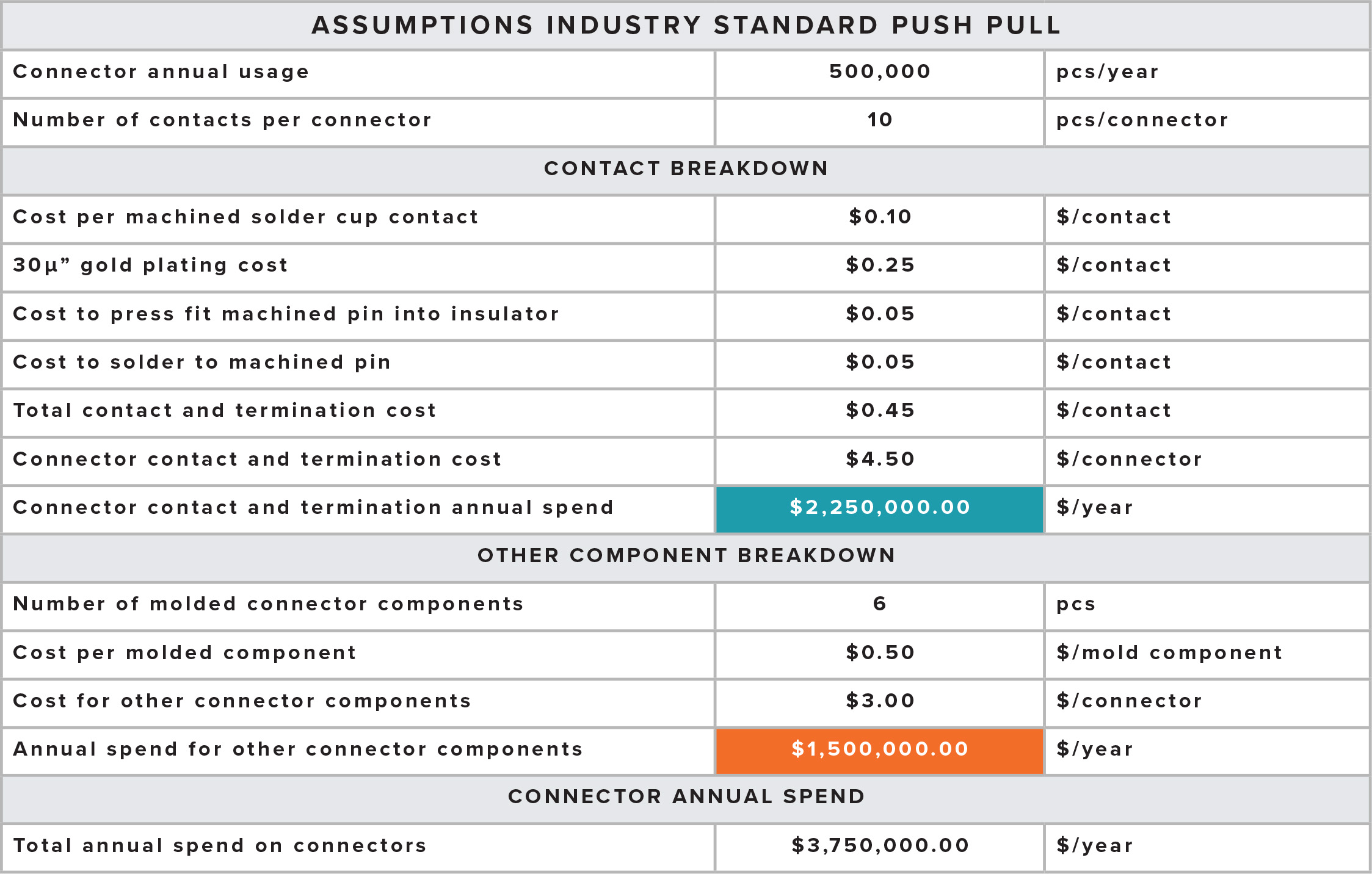

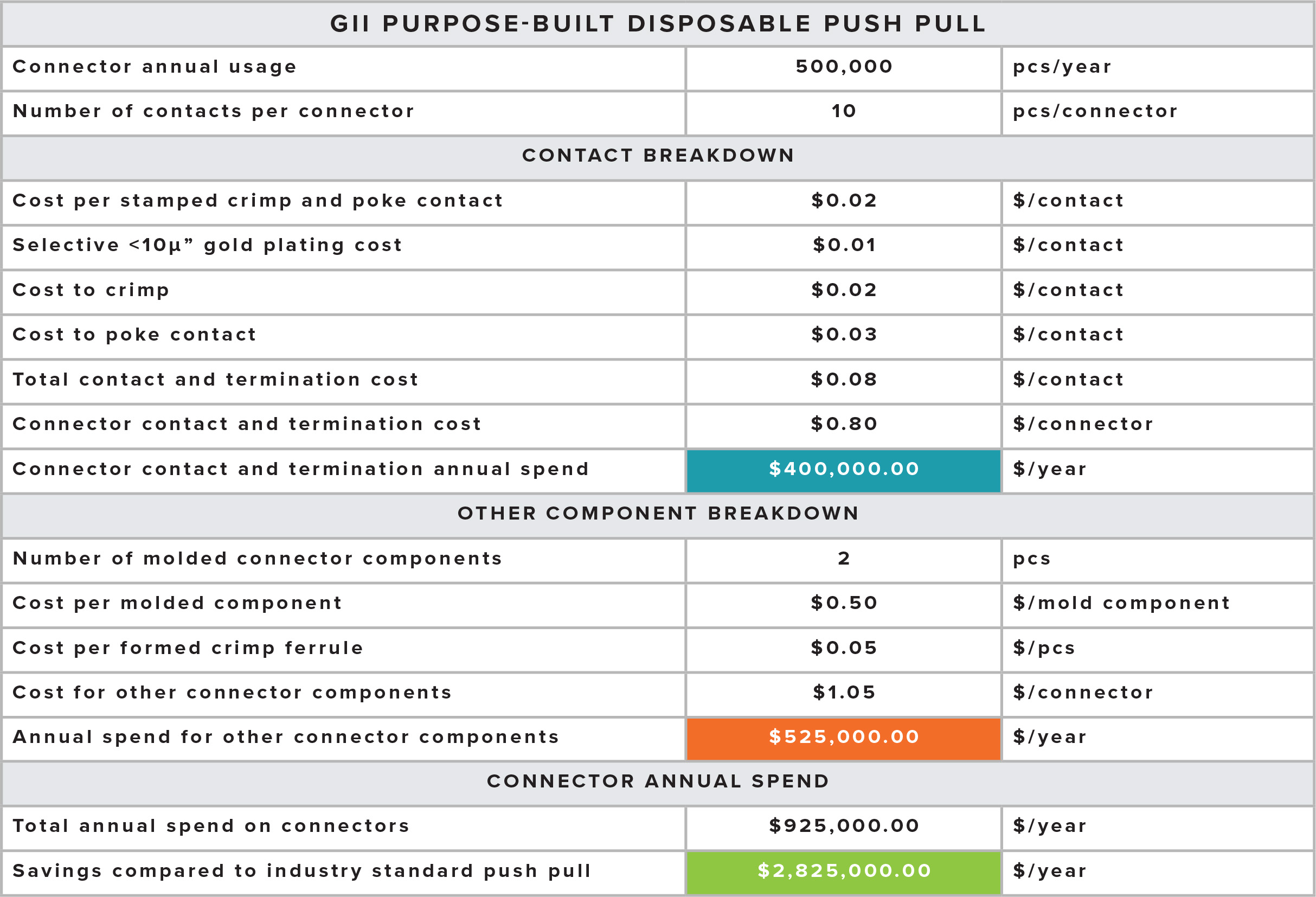

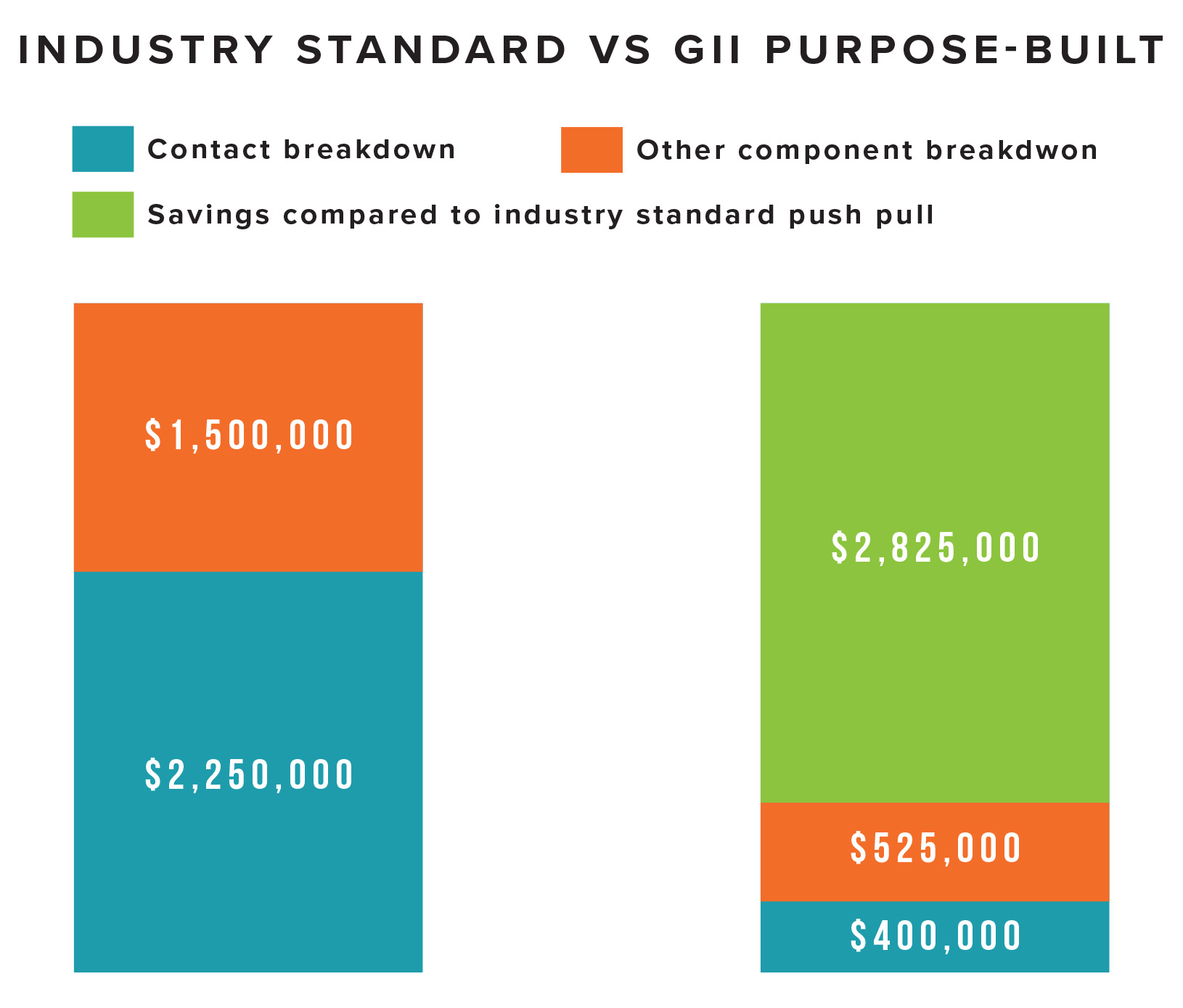

Below is a cost comparison for a

industry standard Push Pull connector vs a GII Purpose-Built Connector:

OVER MOLDED

BANANA PLUGS

RF ablation connectors with over molded banana plugs are the lowest cost option. The contacts are stamped and molded directly into the connector.

OVER MOLDED BANANA

PLUG DESIGN CONSIDERATIONS

LIMITED CONTACT COUNT

• Each contact has high normal force making these types of contacts only suitable for low pin count applications.

• Applications requiring high pin count will run into challenges achieving manageable insertion extraction forces.

NONLOCKING

• These designs lack locking features and rely on the contact force to hold the connector in place.

LARGE ENVELOPE DIMENSIONS

• Due to the size of the contacts and pitch, connector size is impacted significantly with each contact added.

OVER MOLDED BANANA PLUG COST

DRIVERS IN ORDER OF MAGNITUDE

1. NUMBER OF CONTACTS

• Less than $0.05 each at volume

• Labor is also required to terminate the wire to the contact and load into the injection machine load bar.

2. NUMBER OF

MOLDING OPERATIONS

• For more rugged connectors a two over molding process takes place, core than over mold. Each molding operation add labor.

1. TYPE OF CONTACT PLATING

• Banana plugs are typically bare copper (no plating), nickel, and sometimes gold plated.

• For disposable applications bare or nickel plating is typically utilized.

• Bare copper is the lowest cost option, then nickel plated, with the most expensive option being gold plating.

3. MATERIAL

• PVC dominates the disposable market while TPE and silicone complete the reusable market.

• PVC is recommended for EO and gamma while TPE and silicone extend the sterilization options to steam autoclave.