SYNOPSIS

After meeting with the company’s VP of Engineering, our game plan was clear: help this $5 billion, US-based medical OEM (Original Equipment Manufacturers) achieve major cost savings through improved designs, consolidated supply chains, and simplified manufacturing processes.

The Result… $7,000,000 in cost reductions!

Background

The OEM realized this process was complicated, costly, and inefficient – and asked Global Interconnect to help.

Solution

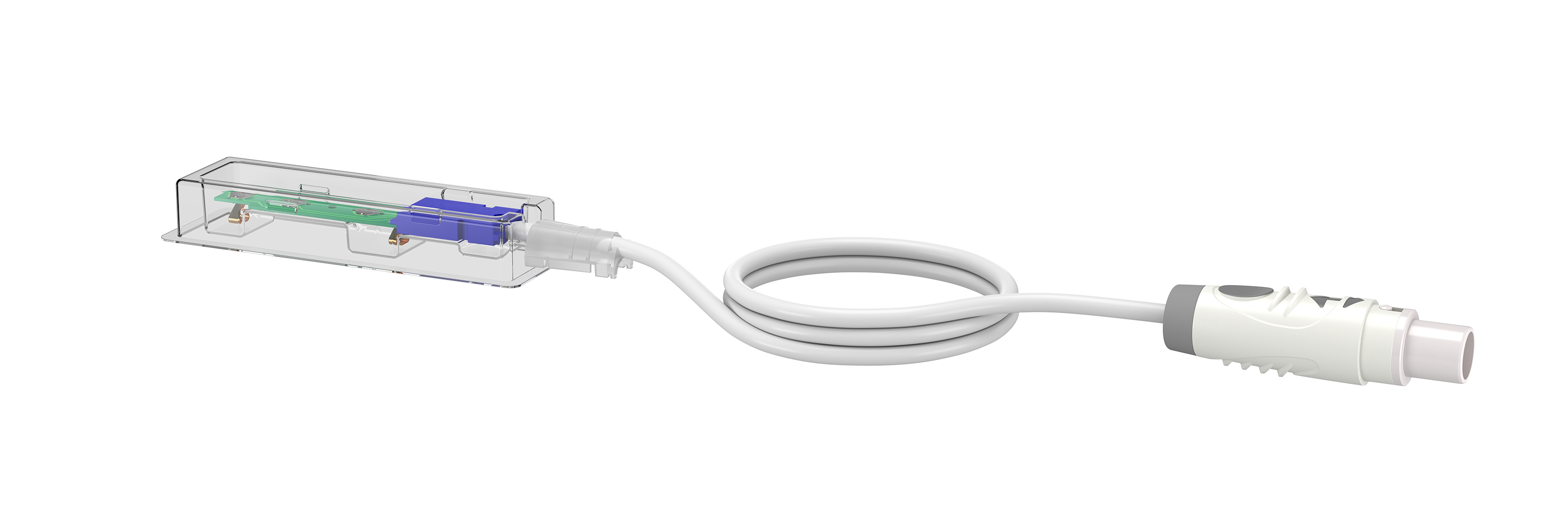

- Components reduced from six to two (the plug and back shell), which snapped together.

- Pin manufacturing costs were reduced by 300% by converting from a machined pin with gold plating to a stamped with gold flash for single use.

- A lower-cost contact insulator material was made possible by converting to stamped pins.

- Reduced need for additional materials by adding contrast to the shells using a laser engraving process instead of a two-part molding process.

Global Interconnect leveraged its expertise in custom cable design and extrusion, printed circuit boards, and complete cable assembly to help further consolidate supply chains, improve processes, and reduce costs.

Implementation

Outcomes

- Significant cost savings of approximately $7 million for 500,000 pieces.

- Consolidated suppliers from 3 to 1

- Reduced steps in the contract manufacturing process by supplying a

sub-assembly, therefore reducing the contract manufacturers’ cost.

The most important outcome? Essential sports medicine treatments and procedures are now getting to market faster and more cost-effectively.