Manufacturing low-cost, high-quality medical devices

starts with choosing the correct connector.

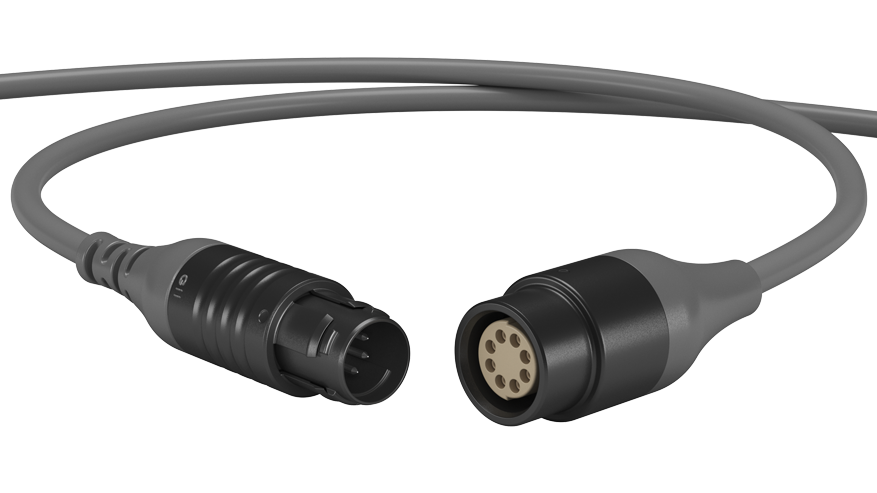

Connectors play a crucial role in the functionality, reliability, and ultimate performance of medical devices.

Based on our extensive expertise in push-pull connectors used in custom cable assemblies for scopes, probes and catheters, here is Global Interconnect’s four-step guide to choosing the correct connector.

1. SINGLE-USE OR REUSABLE?

Determining whether a connector and cable assembly should be single use or reusable involves a multifaceted assessment. Key factors include patient safety considerations, cost implications, environmental impacts, and user preferences. This decision is among the most critical and complex choices in the connector selection process.

2. COMPOSITION, COMPONENTS, MATING, AND STERILIZATION.

Having established whether your connector is intended for single-use or reusable applications, you can now delve into the intricate details of its material composition, components, and mating features. Rigorous adherence to patient safety standards such as IEC60601 and other FDA (Food and Drug Administration) requirements is paramount. Meticulous attention should also be given to the sterilization process, which will be a guiding factor in determining the most suitable connector solution.

3. CATALOG CONNECTORS OR CUSTOM SOLUTION?

A sourcing strategy is crucial for high-volume supply chain dynamics. Catalog connectors do not require development, are readily available, validated, and easy to deploy. Custom connectors require upfront development and investment but offer enhanced scalability, cost savings and tailored solutions aligned with specific requirements.

4. PRIORITIZE THE BUSINESS END.

A common pitfall encountered by medical device OEMs (Original Equipment Manufacturers) is basing their connector selection process solely on the receptacle connector integrated with the generator/console. However, the true focal point lies in the connector that plugs into the generator/console. This is the business end responsible for generating revenue, especially for high-volume singleuse devices such as endoscopes, probes, and catheters..

A robust connector selection process is essential for the success of your product, business — and the well-being of users.

GII (Global Interconnect, Inc): Over 30 years of valuable insights and measurable outcomes. Gii is an ISO13485 and FDA-registered contract manufacturing partner with decades of experience helping medical device OEMs select the right connector solution for their devices. Contact us today For a free consultation with one of our industry-leading engineers